TECHNICAL DESCRIPTION

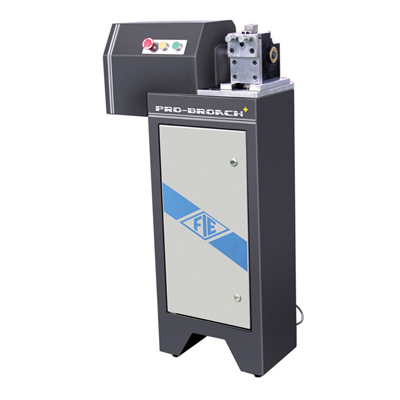

Our motorized broaching machine is a self-contained floor mounted unit, specially designed for cutting Charpy and Izod 'V' and 'U' notches in pre-machined standard 10mm square

Method of Operation

The machine is simple to operate and of robust construction, with large front door to provide access for routine maintenance. The design of the machine provides a comfortable working height.

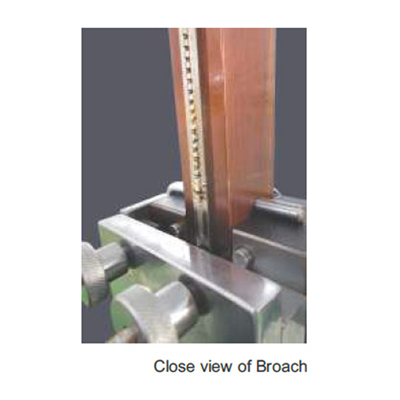

The cutting operation is achieved by drawing a specially designed multi-toothed broach across the specimen.

The broach is drawn into the machine by precision rack and pinion type arrangements via to ensure the broach cuts perpendicular to the specimen clamp, limit switches are fitted for end of stroke travel.

Once the notch depth has been set and the specimen clamped in position, the machine operation is activated via lower and raise push- buttons.

An additional stop button is fitted for emergency use.

An additional stop button is fitted for emergency use. The machine operation is controlled by the lower and raise pushbuttons, which forward and reverse the machine motor, resulting in the broach cutting and return strokes being at a fixed speed.

The motor has thermal overload protection to protect the drive mechanism.

A hand-operated clamp is mounted on the machine top plate at a comfortable working height and ensures that the specimen is held accurately and securely in position.

It is fitted with adjusting screws and an end stop to ensure correct specimen positioning.

A micro-adjustor provides manual adjustment for broach depth of cut and hence the final notch depth. Once set, the adjusting screws provide repeatability for the next specimen.

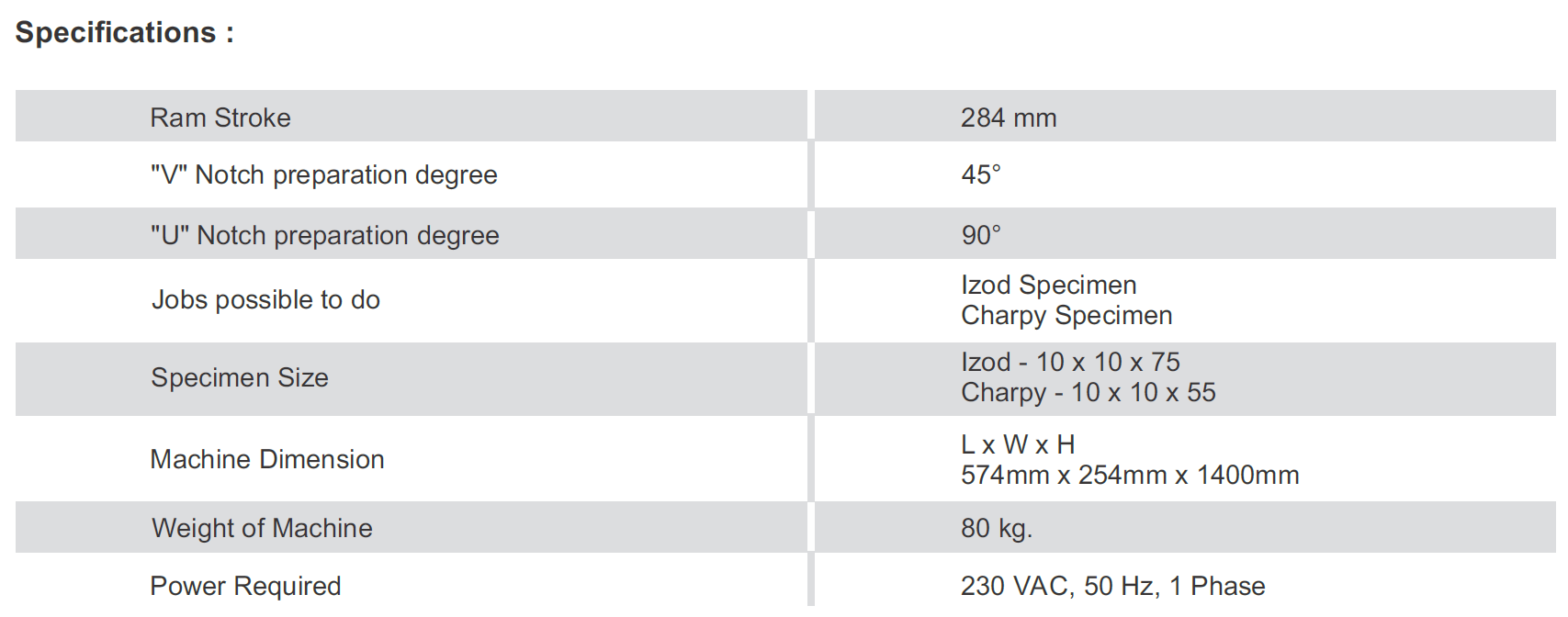

Technical Specifications -

Accessories and Consumables -