Features -

1) Digital display for unbalance indication

Amount and angle for unbalance for both planes displayed on separate DPMS. Hence linear accuracy is very good as compared to analog meter + digit for amount and + Degree for angle.

2) Digital display for RPM indication

A DPM is provided to indicate balancing speed continuously as a standard feature.

3) Auto Stop

No necessary to stop machine once started. It stops automatically after stabilization of unbalance results.

4) Simultaneous Indication

Amount and Angle of unbalance in both planes displayed simultaneously and remains displayed (Stored) till next run. This totally eliminates operation of plane selector and reduces additional time for stabilization of readings in other plane.

5) Key-board

Data of rotor dimensions and balancing tolerance i.e. values of A,B,C, R1,R2,tl11,tl12 are fed by key operation. Hence accuracy of data feedings accurate upto 1 digit.

6) Tolerance Indicators

Separate LEDs are provided for both planes which glow when unbalance is reduced within balancing tolerance.

7) Auto-range

Depending upon whether unbalance amount is more or less a respective course or fine range gets automatically selected till rotor gets balanced within tolerance limits.

Multiplier operation is totally eliminated.

8) Data Store

Data is provided with ‘Self check’ mode which checks proper functioning of digital display. LEDs is cyclic operation. This helps immediate fault detection.

9) Self Check

Panel is provided with “Self-Check” mode which checks proper functioning of digital displays, LEDs is cyclic operation(optional). This helps immediate fault detection.

B) Additional Features on demand

1) Printer :

A matrix printer can be connected through ‘FIE’ software. It shows runs till rotor is balanced within balancing tolerance.

2) Compensation Indication :

‘FIE’ software specially developed with 3-99 component indication,

is suitable for balancing of rotor with fixed locations for balancing

correction.

3 ) Unbalance Correction :

i) Drill attachment 8mm capacity portable drill with supporting overhead railing.

ii) Separate drilling attachment 19mm capacity with a vertical drilling head, manual.

iii) Portable type riveting hammer (piston type) speed 1800 blows/minute, capacity 6mm in aluminum suspected from top with rail.

iv) Tangential belt drive, in addition to standard (suitable for a particular type of rotor for production balancing).

v) Longitudinal movement of right hand pedestal by chain & sprocket attachment.

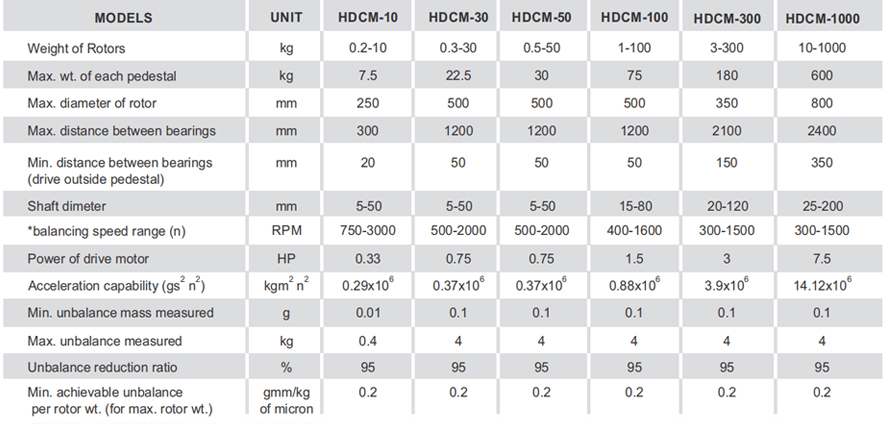

Technical Specifications -