Moving Head Mechanism–Absolute Solution For Hardness Testing Of Odd Sized Components

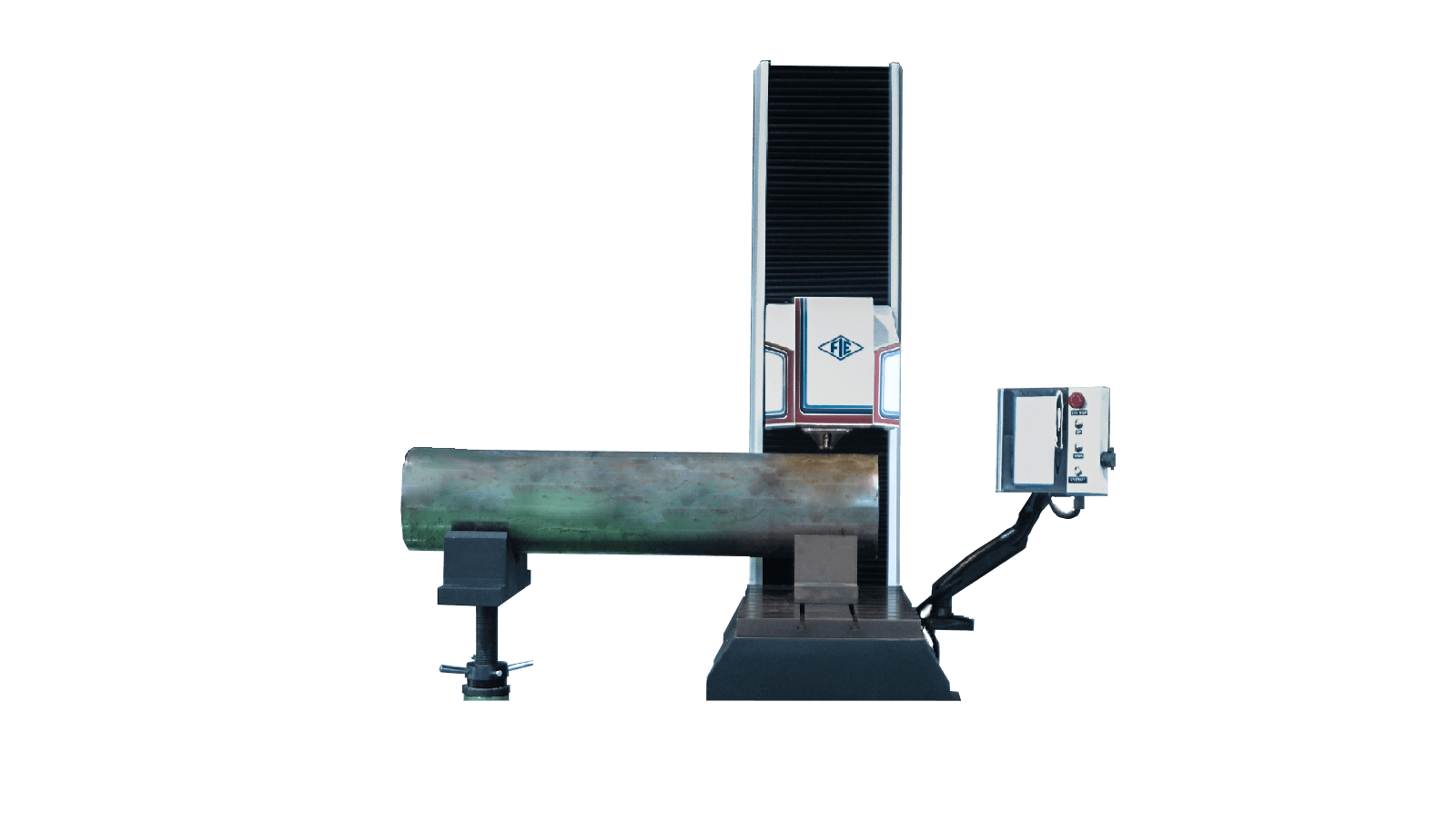

Whether it is a casting, forging, or machined component. Whether it is made up of metal, non-metal, or synthetic material; hardness testing has prime importance in materials testing. Especially when the component is supposed to withstand extreme crushing force. Since its inception, hardness testing has been conducted mostly in a lab under a controlled environment. But the actual test results are useful at an industrial level. The existing hardness testers are mostly tabletop machines and are incapable of testing large-sized components that too on a shop floor. But how can we conduct hardness testing of a cylinder around 50Kg in weight and 125mm in diameter? It is a major challenge for many manufacturing firms to conduct hardness testing of such components on conventional tabletop machines and with pinpoint accuracy. Even though there are many portable hardness testers already available in the market, they have limitations in results and accuracy.

FIE Group’s materials testing machine manufacturing division has taken upon the challenge and successfully developed a range of special hardness testers that are capable of checking the hardness of any odd-sized components with extreme accuracy and repeatability.

Introducing! Fully automatic Rockwell and Brinell hardness testers, RASN-TSFA-MH and BRINMAX-3000. These hardness testers are moving head type and capable of conducting tests on various components with odd shapes and sizes. Let’s have a quick look at both the machines!

The Brinmax-3000 is used for Brinell type testing and RASN-TSFA-MH is for Rockwell type testing (RASN-TSFA-MH comes with an optional Brinell microscope package for Brinell type testing). Both the machines are fully automatic and can be installed on the shop floor also. The machines can be fitted with an X-Y slide (optional) for setting up the component precisely under the indenter. The machines come with a high intensity LED light near the indenter to illuminate the specimen and capturing crisp images of the indentation. Along with the high intensity LED, the machines also have a state-of-the-art image capturing system; coupled with advanced software for getting highly accurate test results repeatedly. Brinmax-3000 has 400 mm throat depth and RASN-TSFA-MH has 150mm, available as a standard option and can be customized as per requirement. Both the machines work on load cell-based closed-loop force feedback system. The test results can be measured using onboard HMI or with a dedicated PC. A component with 1000 mm height can be effortlessly tested on both machines.

Here is a quick specs check of both the machines.

Brinmax-3000

.png)

- 400 mm throat depth as a standard option (can be customized as per requirement).

- Load Cell, Closed-loop, force feedback system.

- Force (load) measurement at the indenter position.

- 0-1000 mm test height.

- Full height linear guideways with precision Ball Screw.

- Large worktable 700 X 520 mm + T-slots and hardened anvil 200mm Removable anvil plate allows inserting special anvils.

- One-click Fully Automatic Operation ensures the elimination of human errors.

- Power LED light near indenter for bright sample illumination.

- Advanced Image processing Software System, Advance test controls [Optional].

- USB connectivity.

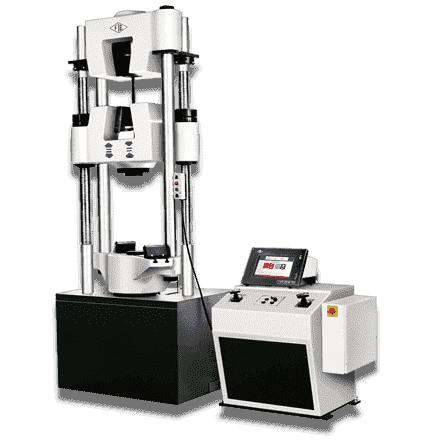

RASN-TSFA-MH

- 180 mm throat depth as a standard option (can be customized as per requirement).

- Load Cell, Closed-loop, force feedback system.

- Force (load) measurement at the indenter position.

- 0-1000 mm test height.

- Full height linear guideways.

- Large worktable 500 x 600 mm + T-slots and hardened anvil 200mm Removable anvil plate allows inserting special anvils.

- Power LED light near indenter for bright sample illumination.

- The software system, advanced tester control [Optional].

- 7’’ industrial touchscreen.

- USB connectivity.

- Optional Brinell microscope package, for Brinell measurements.

But what makes the Brinmax-3000 and RASN-TSFA unique?

A similar type of machine on the market uses a lever arm that has a significant disadvantage on accuracy as the indenter makes a circular movement and either pushes or pulls the workpiece over the anvil. The imperfect non-linear measurements, caused by the specimen movement, requires either mechanical, electronic/software compensation. Both the machines have a perfect linear moving mechanism driven by a high precision ball screw eliminating all possible indenter errors. FIE has positioned the load cell directly above the indenter in the ultimate front part of the machine. In this way, over many years of use, any potential wear and tear inside the hardness tester will not affect the accuracy of the force measurement. The work table can handle large and heavy workpieces. On these models, the vertical capacity can raise to 1000 mm while the table can carry up to a 2.5-ton load.

The Brinmax-3000 is equipped with an advanced image processing Software system, with auto-detection of indentation. Manual positioning of filler lines is no longer required. Also, you can select manual measure mode and have the option of adjusting measurements by touching the screen or using the mouse in case if the surface preparation is not proper. Multiple format reports can be generated as per customer requirement [optional] and can handle any challenging requirement including the control of a 3-axis position system if required. Brinmax-3000 can easily connect via USB, LAN, WLAN, and Bluetooth with any network or quality assurance software.

The RASNTSFA [MH] is equipped with an Industrial ‘’fan-less’’ heavy-duty HMI system. Handle any challenging requirement including the control of a 3-axis position system if required. RASNTSFA [MH] can easily connect via USB, LAN, WLAN, and Bluetooth with any network or quality assurance software. All hardness values can be converted to other scales according to ISO 18265, ISO 50150, ASTM E140.

Customers have also recognized these two machines. Hyderabad based Sandvik Mining and Rock technology Pvt. Ltd. and Worldwide Oilfield Machine, Pune own both the machines. Here is what they have to say about the machines.

"The Brinmax-3000 and RASN-TSFA-MH are one of the advanced machines from FIE. The machines are capable of producing accurate test results repeatedly. The plug-and-play functionality makes both the machines easy to operate; even on the shop floor. Brinmax-3000 and RASN-TSFA-MH are must-have hardness testers for measuring the hardness of odd-shaped and large-sized components.”

Recommended Articles